|

All-Metal Durability - by Chris Heintz

Bush planes need to be rugged, reliable and simple to maintain. "Field maintenance" takes on a new meaning where the pilot literally needs to be able to perform basic maintenance and repair functions in the field. The Zenair STOL Series (CH 701, 750, 801...) is built of all-metal construction. I have over 40 years experience designing and building all-metal aircraft, and there is more than 60 years experience in the industry with stressed-skin, semi-monocoque construction of this nature. Far from being obsolete, metal (aluminum alloy) construction continues to dominate as manufacturers’ choice of construction. Aluminum alloys provide the following benefits: |

.

|

- Low weight / high strength relationship;

- Corrosion resistance, especially with newer alloys and modern primers;

- Low cost and widespread availability;

- Proven durability, and resistance to sun and moisture exposure

- Existence of vast amounts of empirical data on its properties

- Easy to work with: requires simple tools and processes, and does not require a temperature-controlled or dust-free environment, as with composites. Modern blind rivet fasteners have greatly simplified all-metal kit aircraft construction;

- Malleability: easy to form into many shapes, with almost no limit to the shapes it can be formed into;

- Environmentally friendly: no health hazards to worry about when working with sheet metal; recyclable;

- Easy to inspect: construction or materials flaws are easily detected, as are defective parts and damage.

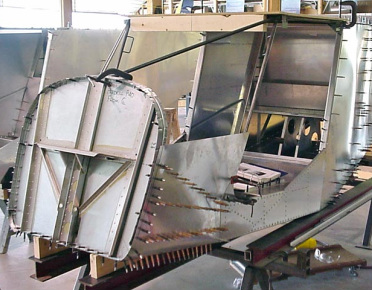

- Simple to repair: rivets and fasteners can be easily removed to replace damaged parts or sections, and individual parts can be replaced without having to replace or rework an entire airframe section.

Thus, aluminum-alloy construction provides the best airframe for a bush plane: 1) Suitable for continuous outdoor storage; 2) Durable and rugged, and; 3) Easy to inspect, maintain, and perform field maintenance. For example, a simple sheet-metal patch can easily be blind riveted onto a damaged area to fly the airplane home.

|

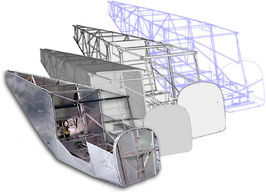

A well-designed sheet-metal aircraft also provides superior crashworthiness, as an impact’s energy is absorbed by progressively collapsing (deforming) the metal structure, as opposed to splintering or shattering upon impact. The landing gear of my STOL aircraft absorbs a lot of energy. It then requires more energy to "rip" it out, and the aluminum stringer frame and stressed-skin construction then need much more energy to start to bend, buckle and twist. The sturdy "cabin frame" will protect the occupants even in an unlikely nose-over of a tricycle gear airplane where the wings, positioned quite a bit higher than the occupants’ heads, will absorb the impact’s energy. Another important advantage often overlooked is the inherent lightning protection that a metal airframe offers.

|

As an aeronautical engineer, it’s easy for me to design a complicated aircraft, and much more challenging to design a simple one. For a kit aircraft to be successful, it must be relatively simple in terms of construction, assembly and systems: Not only is a simple design easier and more affordable to build, but it will be well-constructed by the amateur builder, as there will be less opportunity for errors or poor workmanship. With a simple design, building time will be lower, and less tools and skills will be needed to put the aircraft together, equating to much higher completion rates than complex projects, and once completed, the aircraft will be easier to operate and maintain. Simple systems maximize reliability, while minimizing pilot workload. With 40+ years experience designing and making kit aircraft for amateur builders, we’ve learned to develop aircraft specifically for the amateur builders and sport pilots, offering them complete kits that are quick and easy to build, with minimal tools and skills.

With form following function, my three STOL aircraft designs have an inherent beauty that is more than skin deep once one understands the aerodynamic and construction features that have gone into these designs, making them highly effective short take-off and landing aircraft, while being simple to build and maintain, and providing excellent durability and flexibility.

The original STOL CH 701 and the new STOL CH 750 offer excellent off-airport performance in lightweight and very economical two-seat designs that are easy and fun to fly, while the STOL CH 801 is a true sport utility vehicle, with 1,000 lbs useful load.

Assembly Instructions:

Assembly manuals and all related information necessary for the construction and finishing of your own STOL CH 801-HD kitplane are available on-line at the password-protected "Builder-Reserved" sections of this website. To receive your password, simply follow the instructions here. Note: Only builders with a legitimate serial number and proper identifying information will be granted access to this information.

Assembly manuals and all related information necessary for the construction and finishing of your own STOL CH 801-HD kitplane are available on-line at the password-protected "Builder-Reserved" sections of this website. To receive your password, simply follow the instructions here. Note: Only builders with a legitimate serial number and proper identifying information will be granted access to this information.

|

"SD" Manuals and pictures:

(New material added as available) |

|

"HD" Manuals and pictures:

|

|

Engine installations: |

|

|

© Zenair Ltd. 2011-2024

|