.

The underlying philosophy behind the STOL CH 801-SD kit is to provide the builder with everything needed to complete the STOL CH 801-SD airframe - with only basic tools and skills. Drawing upon Zenair’s 35 year kit aircraft manufacturing and design experience, the kit is developed for maximum ease of construction, while using only materials and parts of the highest quality. The STOL CH 801-SD kit is estimated to require only about 750 hours to build from the complete factory-supplied kit.

|

All you'll need to get started is a level workbench and basic hand tools. The detailed and illustrated photo-manuals guide the builder through the entire kit assembly process following a logical step-by-step sequence. All kit components, parts and hardware are supplied – labeled and numbered for easy identification. Every airframe bolt, fastener, and rivet is supplied with the standard kit. |

.

|

The airframe kit takes straight-forward and basic assembly-work to put together using only simple tools, such as an electric hand drill, a hand rivet puller, ‘Cleco’ temporary fasteners, a set of wrenches, a few hand files, sheet-metal snips, etc. Importantly, virtually no jigs and fixtures are needed in the building process, as all sections are built up from the flat workbench. A bending brake, shear or other machinery is not needed, and assembly is easily done in a single car garage or basement workshop.

- BASIC HAND TOOLS: Tape Measure, Electric Hand Drill, Hand Rivet Puller, Cleco Temporary Fasteners, Sheet Metal Snips, Hand Files, etc.

- Related Topic: Required Tools & Workshop

|

While previous aircraft building experience and sheet-metal skills are always an asset, the STOL CH 801-SD kit and assembly instructions are developed specifically for the inexperienced novice builder. The simplicity of construction, quality of parts and components, and the completeness of the kit translates into low build-times and a very high kit completion ratio, even for novice builders. |

The STOL CH 801-SD kit will meet the requirements for amateur-built (experimental) categories in the United States and Canada, as well as in most countries around the world.

.

|

In the kit, all the wing ribs and fuselage bulkheads will be supplied pre-formed. For example, the internal wing ribs are first press-formed, with lightening holes cut and flanged, and then hand finished at the factory for a perfect ready-to-install fit. The heavy-duty wing spars come complete with all solid (bucked) rivets already set by factory professionals. Surface skins - wings, ailerons, elevator, rudder, and fuselage - are ready for fitting.

|

Pre-assembled parts (such as the wing spar) are factory-treated with zinc-chromate primer for maximum corrosion resistance. Welded parts, such as the engine mount, control assemblies, and fuel tank, will come factory welded and ready to install.

The STOL CH 801-SD kit is complete: the heavy-duty landing gear system, hydraulic brake system, fiberglass wing tips, control systems, welded aluminum fuel tanks, etc., are standard equipment in the complete airframe kit.

The STOL CH 801-SD kit is complete: the heavy-duty landing gear system, hydraulic brake system, fiberglass wing tips, control systems, welded aluminum fuel tanks, etc., are standard equipment in the complete airframe kit.

|

The STOL CH 801-SD builder is able to start assembly right away after taking delivery of the kit. Working from a flat table, the builder can immediately begin assembly - simply by measuring, drilling and riveting, and thus progress through the whole airframe section by section, aided by the detailed step-by-step manuals and visual photo guides supplied with the kit. Building the all-metal STOL CH 801-SD is straight forward, requiring no complex jigs, and no messy (and hazardous) doping or epoxy work is involved. With the proven and simple all-metal construction technique, the STOL CH 801-SD builder does not have to worry about having a temperature controlled dust-free work-shop environment, and does not have to mix compounds and wait for parts to cure. |

Assembly of the kit is divided into many small modular projects, allowing the builder to focus on one small section at the time before moving on to the next. For instance, the wing is divided into numerous sub-sections. This modular sequential approach minimizes required workspace, and also allows builders to buy the kit sections as they progress through the project.

Designer Chris Heintz' extensive light aircraft engineering experience has allowed the development of an aircraft that minimizes the actual number of parts in the aircraft (thus saving the builder cost and and assembly labor) and Zenith Aircraft's comprehensive kit manufacturing experience and capability allows us to do factory sub-assemblies and components for the basic kit parts. Our basic philosophy with the kit is to provide all the parts and components ready for assembly, so that they require only basic skills and tools to be put together. If an assembly requires a special jig or critical measurements, the assembly is pre-jigged or built at the factory or supplied with the jig with the kit. Critical and time-consuming assemblies, such as the control systems, are completed at the factory and supplied ready for final assembly.

Customers will find the STOL CH 801-SD kit to be easy and enjoyable to build, even for novice first-timers, and it should take less time to put together than most two-seat kit aircraft on the market.

Preview the assembly manuals

Customers will find the STOL CH 801-SD kit to be easy and enjoyable to build, even for novice first-timers, and it should take less time to put together than most two-seat kit aircraft on the market.

Preview the assembly manuals

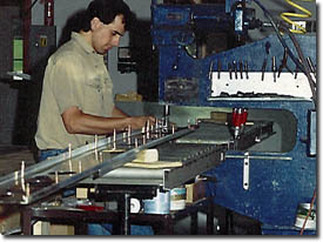

Parts Manufacturing at Zenair Ltd:

|

|

© Zenair Ltd. 2011-2024

|